Upkeep and repairs

Latest updated Tuesday, October 8, 2013, 3 comments

A wood-strip built boat is in principle maintenance free. The epoxy layer prevents moisture and oxygen from entering the wood cells and thus makes life impossible for wood destroying organisms. At the same time it prevents the dimensional changes that would otherwise would break glue joints and finishing.

But in practice the boat need some maintenance.

Scratches arise while coming to shore, banging against piers and with handling in garages and on cars roof. Most scratches go only through the varnish and can be fixed with a little sanding and a coat of varnish. If the repair is still visible, it can help to go over the canoe with a little rubbing or polishing compound (make sure there is no silicone in the rubbing compound - it can make future finishing impossible).

After a couple of years and a number of small scratches and wear it may be time for a complete refinishing - a light sanding and a new coat of varnish.

After a couple of years and a number of small scratches and wear it may be time for a complete refinishing - a light sanding and a new coat of varnish.

Deep scratches, where the fiberglass structure is stressed to reveal the fabric can also be repaired functionally with a light sanding and a new coat of varnish. But the white color indicates that the epoxy has released from the fiberglass threads under stress and such a damage should ideally be sanded down and rebuilt with epoxy and fiberglass.

Scratches that go down into exposed wood should of course be dealt with as soon as convienient. Not so that a trip needs to be aborted – a couple of weeks are no problem, but gradually the wood begins to darken and loses its structural strength. Sand away the fiberglass around the scratch, let the wood to dry out (perhaps assisted with a little heating), rebuild the fiberglass/epoxy laminate and varnish. Such a repair will be lighter in color than the rest of hull, but the difference is evened out gradually as the rebuilt area darkens. It takes however a couple of years.

Keep an eye on the gunwales which are vulnerable to wear. Even small damages here can let water into the wood. Then the fiberglass cracks at the decks edge when the wood swells. Such damage should be sanded down, the wood allowed to dry out and new finishing be built up (epoxy/fiberglass/varnish).

When the varnish becomes too thin - of much use or wear – the epoxy can be damaged of UV-rays. Such damage is visible when the surface finishing becomes “misty” (milk white and streaked). If this happens the finishig coat should be sanded away and a new coat applied.

Ropes used on the boat are weakened by UV-rays and must be changed every few years.

A way to keep the bright shiny and fine surface of a well built canoe is to go over the surface with a fine rubbing or polishing paste a few times a year. A final waxing gives a high class finish but requires areful cleaning before refinishiong (Again! check carefully that the polishing or rubbing compound contains no silicone).

Storing

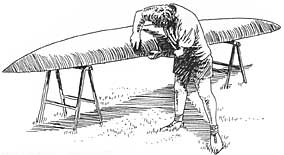

Keep the canoe out of the sun’s rays, in a garage or under a tarpaulin. Set it on a pair of saw horses or hang it from nylon bands or ropes.

Pad the saw horses or the roof rack with pieces of carpet or tube isolation made off polythene foam to protect the surface against scratches.